At HENGLIDA, we strive to continually develop and produce a diverse range of innovative, high quality products which will best suit our customers’ specific requirements. These products are manufactured utilizing outstanding-performance materials, such as high-speed steel, cemented carbide and many others. Henglida constantly analyzes our production techniques and operational procedures to produce products in the absolutely most cost-effective manner possible, saving our clients investment dollar and increasing their profit margins. For the top industrial blade and knives manufacturer choose Henglida and your clients and your bottom line will be glad you did!

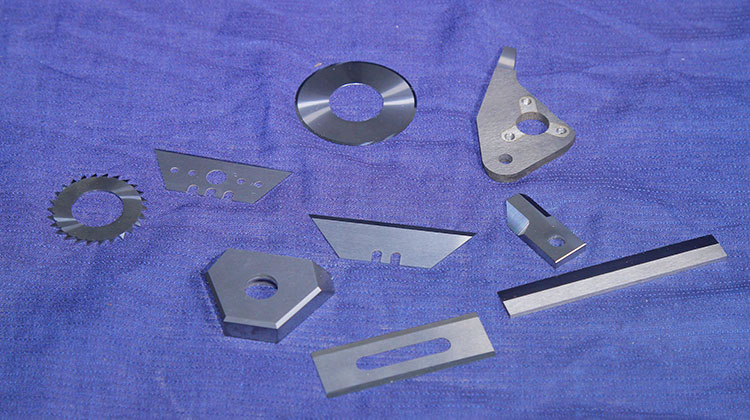

HENGLIDA has earned respect and satisfaction of clients, not just because our cutting tool product processes and advanced levels of precision, but more importantly because the product features reliable quality. Every piece of the cutting tool at HENGLIDA is bound to undergo several dozen production processes. Quality assurance procedures are in place throughout every stage. The entire manufacturing system is conducted under strict quality control. Strong persistence of our traditional technique and and deep-seated corporate culture contribute to the consistent quality of HENGLIDA’s blade tools. Our main product catalogue includes: tungsten carbide blades, high-precision machine knives, press brake tooling etc. These products are used for precise slitting and transverse cutting of metals and nonmetals, as well as sheet metal processing and papermaking applications. They are also suited for household paper, plastic film, chemical metallurgy, rubber tire and various packaging industries.

This type of products is mainly used in filling machine, sealing machine, wrapping machine, multifunctional packing machine, automatic pillow type packing machine etc. which are widely used in food, medicine, household paper packing, rubber, film and other industries.

Producing this type of product is a great challenge. It can be used in processing material, rubber, fiber material (such as steel tire cord and KEVLAR) etc. For specific products, it can be used in producing tyres, films, conveyor belts and cog belts. It can offer enough strength in both cutting and shearing so that the cutting process will not cause any problems.

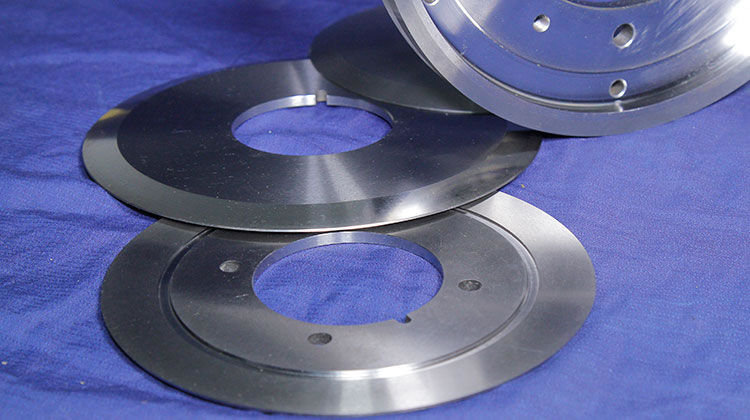

This product adopts special steel technique and advanced processing technology to realize high precision and high quality slitting. So it can meet the requirements of various customers. The slitting blade is mainly used in slitting paper, film, gold foil, silver foil, tape etc. For this usage, the cutting resistance should be the smallest, and the wear resistance should be the biggest. So, we use independently developed CNC grinding machine to process two slopes of the upper slitting blade. Meanwhile, we use CNC grinding machine to process internal and external arc of the lower slitting blade. This process can significantly improve the product quality and production efficiency.

It is the latest circular knife which is inlaid with carbide single-sided or double-sided. It is used in imported high speed rewinder for cutting toilet paper and writing paper. This product has the following advantages: good wear resistance, long sharpening period, superior to similar products at home and abroad. So, many manufacturers of high-end slitter rewinders are long-term partners of Henglida.

Circular dished knives have stable quality and high precision. The strip material cut by it has no burr and no scratches on the surface.

The main blades used in paper packaging industry include cardboard die-cutting rule, crosscut circular saw blade, thin alloy slitting blade, paper guillotine knife, upper slotting blade, lower slotting blade, corner cutter etc. The thin alloy slitting blade is widely used in corrugated paperboard production line worldwide. It is famous for its neat incisions, no burrs and long service life.

This kind of knife uses superior materials like inlaid high speed steel and carbide so that it has higher wear resistance and long-time sharpness. Thus, it is used in production of paper, pulp etc. This kind of products include the following types: lower circular blades of rewinder, paper cutting blades, flail blades, corrugated paper cutting knife, circular blades, tissue cutter etc. Roll toilet paper circular blade (large whirling blade) has high wear resistance, rust resistance, higher precision (equipped with the grinding wheel developed by our company), so that it can produce rolls with no burr, no saw trace, no blackening.

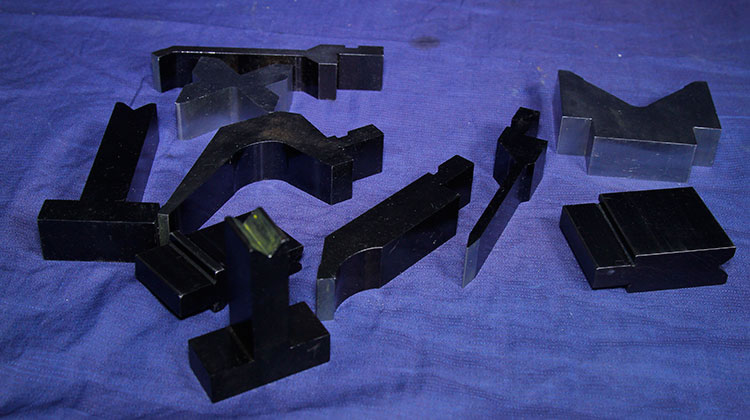

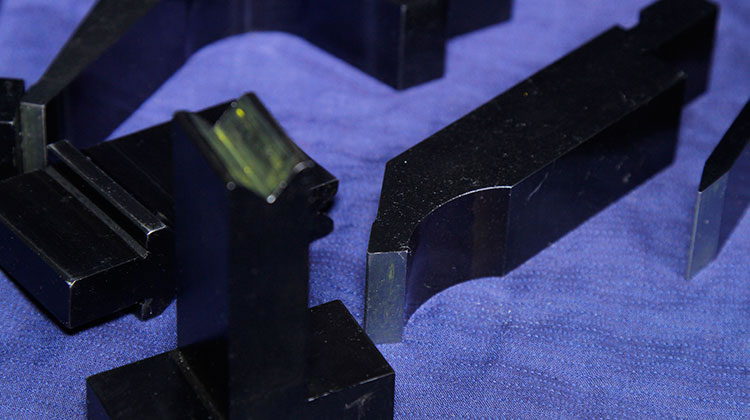

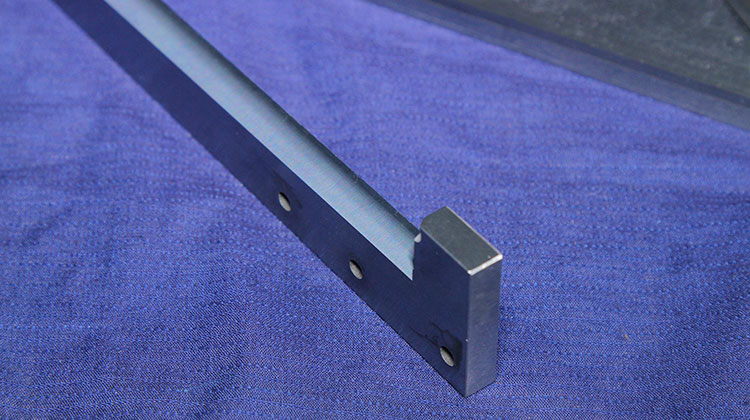

This mold can be divided into upper mold and lower die of bending machine. It is used for molding and separating of sheet metal press working. It has the following features: high strength, high toughness and good wear resistance. We can also produce mold, pole, steel pole, bending forming round mold, multi-angle die of CNC bending machine according to requirements. We can also offer elbow mold, knife mold, cylindrical, u-shaped and bending embossing die, container mold, lamp post die, shearing blades, map processing, non-standard design etc.

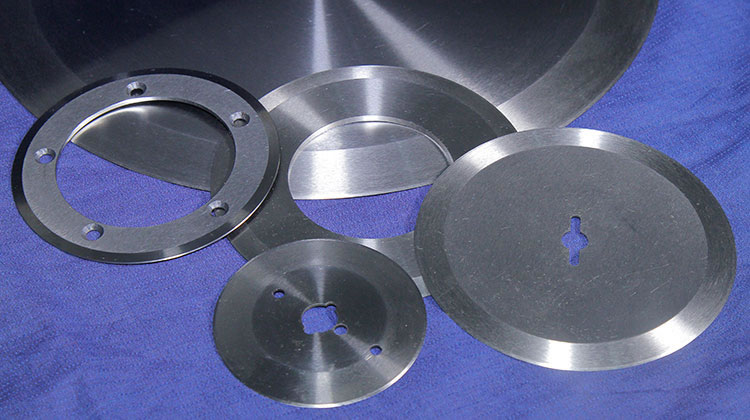

This type of product includes all kinds of high precision tungsten steel blade, circular slitting knife, alloy and inlaid alloy blades. They are widely used in cutting copper foil, aluminum foil, Cr film and other nonferrous metal materials in electronic industry. They can also be used in high precision cutting of steel plate and packaging materials as well as cutting in printing, chemical fiber and packaging industry and milling of metal blanks.

It is an important part of the shredder. The shredder blades can be divided into single shaft shredder blades (square blade) and multiple shaft shredder blades according to the structure of the shredder. We can offer steel or inlaid steel blade according to the precision design.

This type of blade has high wear resistance and high precision because it has good concentricity. When being tested, the edge of the blade must be magnified more than 100 times. Materials that cut by lithium battery blades have smooth incisions with no burrs. And you don’t need to change the blades so often because it has long life-span. It also has high cost performance, so that it is an ideal blade for the lithium battery industry to reduce the slitting cost and improve the quality of slitting.

Henglida Machine Blade Co., Ltd.

Add.: 1 Henglida Road, Bowang Economic Zone, Ma'anshan City, Anhui Province, China

Tel.: +86-555-6762129

Fax: +86-555-6761259

E-mail: sales-jack@cnhenglida.com

Contact (Supervisor): Jack Wu