HENGLIDA has invested heavily in the industries most advanced production machinery including: 16 state-of-the-art blade production workshops which occupy an area of more than 40,000 square meters. With the support of an industry recognized R&D team, advanced technologies and cutting-edge heat treatment equipment, we have an excellent production capacity to process a comprehensive range of industrial knives, so with Henglida, you will never be left waiting for back ordered products!

Every HENGLIDA product must undergo dozens of testing and inspection processes for the purpose of quality control. We only use high-quality raw materials from the best-in-class worldwide suppliers. The use of well-established forging techniques improves the performance of our raw materials. The advanced heat treatment method ensures our machine knives possess high precision and a long service life.

According to the characteristics and classification of our products, we have exclusively set up 7 independent workshops. By utilizing over 400 sets of processing equipment and our own hard-earned expertise we are consistently perfecting our comprehensive range of manufacturing techniques, resulting in exceptional-quality products.

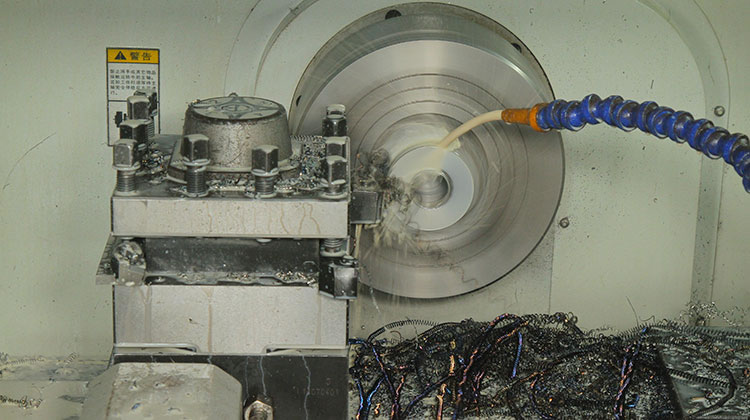

Our company has built an outstanding group of professional machine operators who use numerically-controlled lathes to complete surface treatment on blade products. We have also established a highly organized product storage area, which delivers an excellent degree of convenience for transporting both finished and semi-finished products. A wide variety of CNC grinding machines in the workshop ensures our products possess extremely high levels of precision and geometric tolerance. This also ensures our final products are monitored in real time when being manufactured in-house.

Unlike other workshops, our engineering department uses high-precision lathes and advanced 4-axis CNC machines for processing of stamping moulds used in large bridges and electrical equipment projects.

In addition, those products that need to be specially processed will be managed strictly in our workshop to prevent Henglida technology from being copied. Also we have employed cutting-edge equipment from other countries, which ensures our products are fully qualified. Once precision machining has been completed, wire cutting machine tools are used to perform intelligent cutting, ensuring highly precise products.

Henglida chooses the first class material suppliers both at home and abroad such as Assab, Nachi-Fujikoshi, Eramet, Baosteel, Fushun special steel, Zhongte, AT&M-HEYE, to ensure the high quality of raw materials.

Steel plate

Steel plate Cutting raw material according to standard

Cutting raw material according to standard

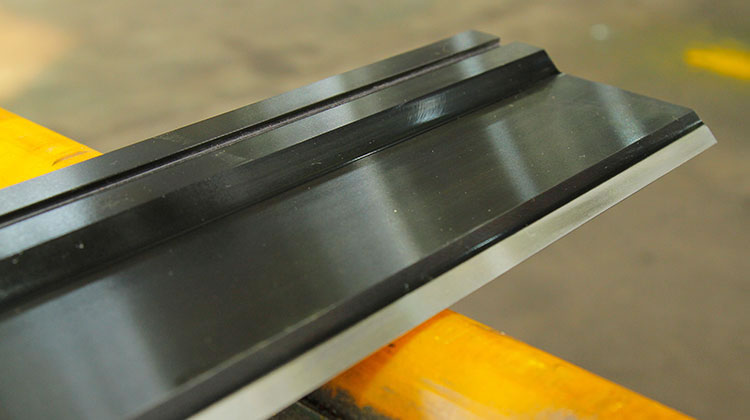

Blade edging

Blade edging

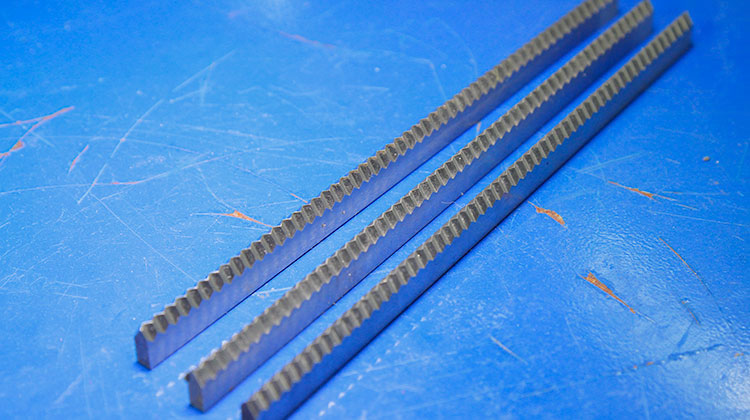

Processing gear grinding

Processing gear grinding Fine machining by lathe

Fine machining by lathe

Operating equipment

Operating equipment Working 4-Axis CNC

Working 4-Axis CNC

It is used in trimming die of steel bridge

It is used in trimming die of steel bridge It is used in power tower and other large projects

It is used in power tower and other large projects

The professional forging shop of our company has mature forging process to improve the performance of raw materials. By this process, our products can play a major role in a variety of environments.

Steel plant

Steel plant Neatly placed steel to be treated

Neatly placed steel to be treated Steel processing by sawing machine

Steel processing by sawing machine Cutting finished steel to be processed

Cutting finished steel to be processed Fully functional workshop

Fully functional workshop Forging forming

Forging forming

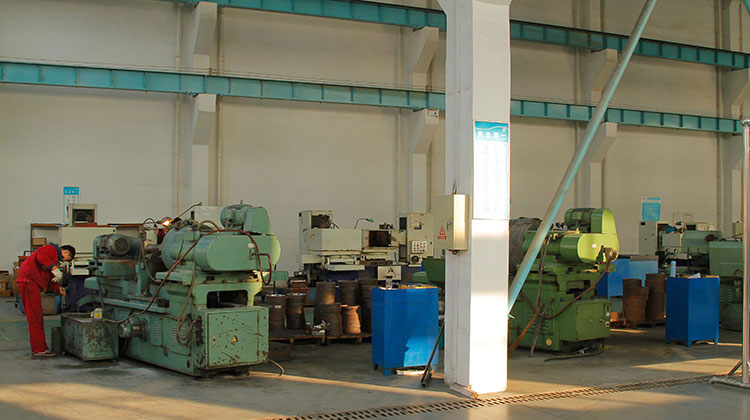

Cutting, traverse cutting and abnormity blade processing workshop

Cutting, traverse cutting and abnormity blade processing workshop

Lathes

Lathes Advanced equipment from abroad

Advanced equipment from abroad

Advanced processing equipment

Advanced processing equipment Finished blades

Finished blades

Professional lathes

Professional lathes Processing shop with cooling system

Processing shop with cooling system

Advanced equipment

Advanced equipment Finished blades

Finished blades

Rotary slitting knife testing

Rotary slitting knife testing

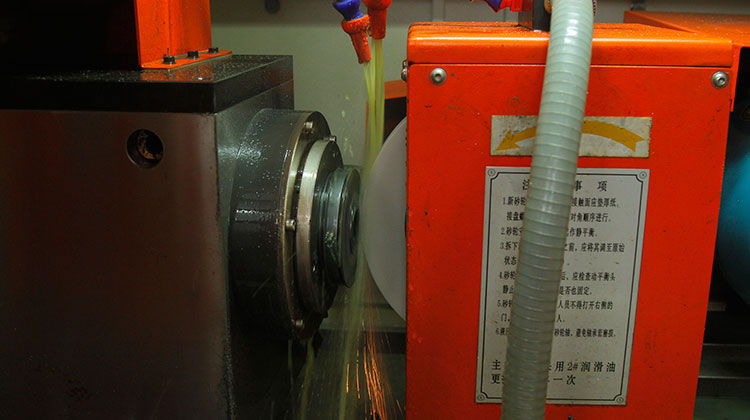

Surface grinding of rotary knife

Surface grinding of rotary knife Edging of flat round knife

Edging of flat round knife Workshop

Workshop Testing of blade concentricity

Testing of blade concentricity

Processing of large blades

Processing of large blades Semi-finished storage area for products passed inspection

Semi-finished storage area for products passed inspection Processing rewinder machine blades and slotting blades

Processing rewinder machine blades and slotting blades Finished blades

Finished blades

This factory is equipped with various CNC grinders. These machines guarantee that the precision, flatness, parallelism, roundness, concentricity and geometric tolerances of the products can reach the advanced machining accuracy in the world.

CNC bending machine mold processing workshop

CNC bending machine mold processing workshop Large processing equipment

Large processing equipment Planning machine

Planning machine Milling planer

Milling planer Finished blades

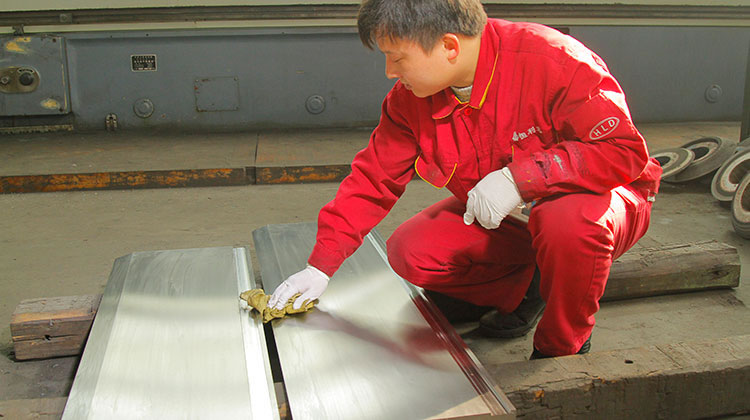

Finished blades Cleaning the blades

Cleaning the blades Precision grinding machine

Precision grinding machine Grinding

Grinding

Workshop in new factory

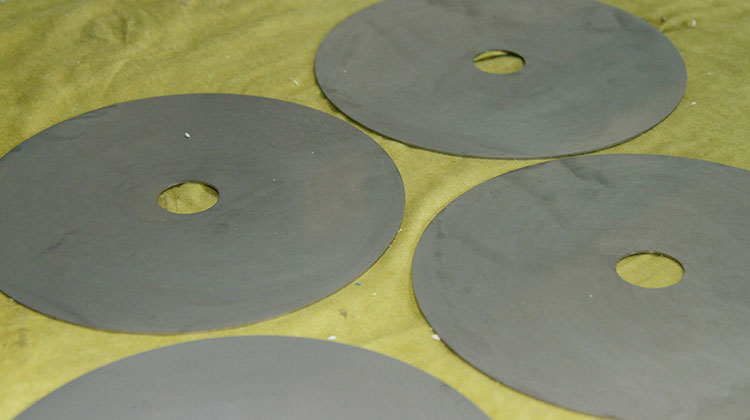

Workshop in new factory Workshop for slitting blades and fine gasket

Workshop for slitting blades and fine gasket

Operating machine

Operating machine Grinding

Grinding Flat opening and polishing

Flat opening and polishing Testing

Testing

The process from alloy to finished product is completely carried out within the company. Thus every step can be monitored in real-time to ensure stable quality.

Cemented carbide processing workshop

Cemented carbide processing workshop Semi-finished blade

Semi-finished blade

This workshop is equipped with advanced devices such as vacuum furnace, carbonitriding furnace, salt bath furnace and deep cooling furnace etc. All the devices form a perfect heat treatment system to ensure the product quality of Henglida.

Blade produced by special process

Blade produced by special process Neatly arranged special cutting knives

Neatly arranged special cutting knives Line cutting workshop

Line cutting workshop Intelligent cutting by line cutting machine

Intelligent cutting by line cutting machine Vacuum furnace workshop

Vacuum furnace workshop Heat treatment equipment sets

Heat treatment equipment sets

Advanced heat treatment equipment

Advanced heat treatment equipment Specially introduced heat treatment equipment

Specially introduced heat treatment equipment

Henglida Machine Blade Co., Ltd.

Add.: 1 Henglida Road, Bowang Economic Zone, Ma'anshan City, Anhui Province, China

Tel.: +86-555-6762129

Fax: +86-555-6761259

E-mail: sales-jack@cnhenglida.com

Contact (Supervisor): Jack Wu